- HOME

- Know Your Tech

- How simple tweaks can lead to efficient manufacturing workflows

How simple tweaks can lead to efficient manufacturing workflows

- Last Updated : June 12, 2025

- 12 Views

- 4 Min Read

Across every industry, smooth workflows are the backbone of reliable output—whether you’re processing orders, handling customer requests, or coordinating production lines. But in an industry like manufacturing, where speed, accuracy, and coordination are critical at every stage, even small inefficiencies can directly impact production schedules and margins. It combines complex systems, time-sensitive coordination, and high volumes of repetitive tasks.

While digitization promises speed and accuracy, clunky digital workflows often do the opposite. Rather than storming ahead with expensive software upgrades or elaborate automation scripts, the smartest path is to first diagnose exactly what’s broken—and why.

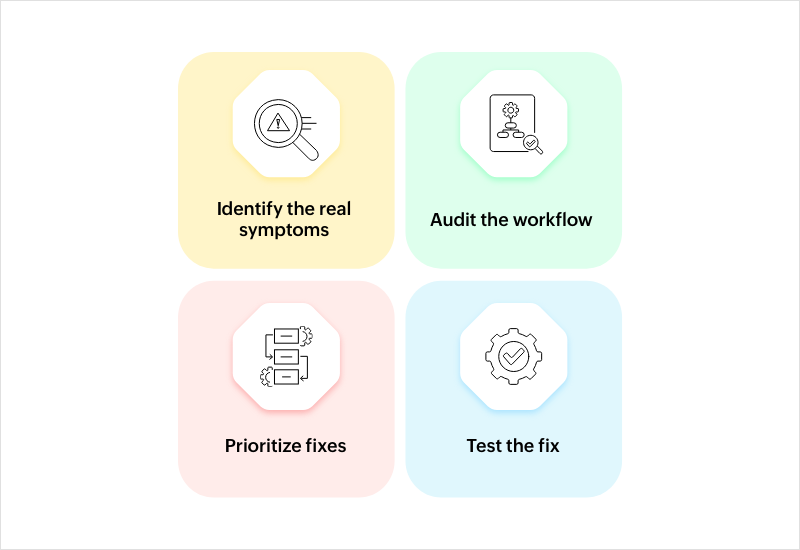

Step 1: Identify the real symptoms behind the digital friction

Why this matters: It’s easy to assume that a slow screen or a missing approval notification is simply a software problem. But in reality, those are just symptoms. If you treat only the surface issue—say, by buying a newer ERP module—you risk masking the root cause, only to see the same issue pop up elsewhere.

Go beyond the diagrams

Your process flow charts may show a neat line from order received to materials issued, but they won’t reveal where your team actually gets stuck. Talk to the people on the ground—machine operators using the MES, production planners juggling schedules in spreadsheets, and QA inspectors entering results into quality modules. Ask them where they lose ten, twenty, or even thirty minutes every day.

Spot the choke points

Are approvals lining up in a backlogged queue? Do purchase-order requests disappear into "pending" limbo? Track the common troublemakers. You might find that the approval screen requires five clicks across two tabs each time someone clears their browser cache, or that the MES (manufacturing execution system) only refreshes data every hour, causing your inventory team to run without clear visibility.

Step 2: Audit the workflow with context from actual users

Why this matters: Once you’ve pinpointed a frustrating process, break down every step with the people who do it day in and day out.

Map the journey

Pull up one process (e.g., purchase requisitions, quality-report submissions, or production-order tracking) and list each action in sequence. For purchase requisitions, it might look like:

a. Operator fills out Form A in the ERP.

b. Requisition data is manually re-entered into the MES.

c. Finance generates a PO in its own system.

d. Confirmation emails go out via yet another platform.

Ask the three key questions at each step:

- If a step exists only to satisfy an audit requirement, could you batch-process it at month-end instead of breaking your flow?

- Can the system auto-populate fields from existing data or trigger the next step without a human click?

- How often do users hop between systems and re-type the same information?

Document inefficiencies

Note which steps add real production value and which ones exist only because you’ve always done it that way. Seeing duplicates makes it easier for you to propose a tweak that improves workflow efficiency across existing workflows.

Step 3: Prioritize fixes with a quick impact-vs-effort matrix

Why this matters: Not every improvement is worth the same investment. A simple tweak that saves ten minutes a day for ten people can outweigh an upgrade that affects only one team.

Draw your 2x2 grid

On one axis, mark effort (low to high). On the other, mark impact (small to large).

Populate quick wins

Look for changes that are low effort but high impact. For example:

- Prefilled forms: Set up your ERP or low-code tool to auto-fill known data (vendor name, unit cost) when creating a requisition.

- Auto-routing rules: Send purchase-order requests directly to the right approver based on department instead of manual forwarding.

- Dashboards: Replace daily status emails with a live view of pending approvals or material availability.

These types of fixes improve efficient workflow management without disrupting the larger system.

Ignore the fluff

Before you commit time or budget, ask: “Do the diagnostics or pilot data actually show a need for this?” If a proposed upgrade or tool doesn’t address one of your documented pain points, de-prioritize it. Not all automation tools will solve your problems, so use only what supports your workflow management goals.

Step 4: Test the fix with a pilot team first

Why this matters: Rolling out a change across an entire plant can introduce new problems, but setting up a small pilot can keep risk low and feedback rapid.

Pick one focus area

Choose the one process that’s driving the most pain right now—like the materials-request loop or the daily quality-report submission. This keeps the scope small enough to manage and gives you clear before-and-after comparisons.

Implement a single tweak

For your chosen process, introduce a targeted improvement: perhaps an automated notification when stock falls below a threshold, a new form trigger that skips unnecessary approval steps, or a simplified data-entry screen.

Measure the right metrics

- Turnaround time: Did approval hours drop?

- User satisfaction: Have operators stopped raising the same complaints?

- Manual-step count: How many clicks or data entries were eliminated?

Gather feedback and refine

Invite pilot users to a quick debrief: What worked? What didn’t?

Use these insights to tweak labels, adjust notification timing, or refine routing rules before rolling the change out more broadly.

Moving forward

Digital workflows in manufacturing should simplify operations, not add layers of complexity—and that only happens when you design around real user behavior.

Diagnose first

Talk to your people. Observe what actually happens in the ERP, MES, or inventory tools.

Tweak smart, not hard

Prioritize low-effort, high-impact fixes like prefilled forms, auto-routing, and real-time dashboards before chasing big, labor-intensive upgrades.

Pilot rapidly

Test with one team, one shift, or one process. Measure improvements, gather feedback, and then scale.

And when you’re ready to build and iterate on these improvements, a low-code platform like Zoho Creator will help you move forward. It lets you drag and drop workflows, set up form and approval rules, and schedule automated actions in minutes without calling IT or waiting for months of development. It’s a faster and smarter way to optimize workflow management, automate routine steps, and reduce the burden of manual tasks—all while driving efficient workflows from the ground up.

Ann Elizabeth Sam

Ann Elizabeth SamHey! I'm Ann, and I work as a content writer at Zoho Creator. I'm exploring the SaaS world through various forms of content creation. Outside of work, I love dancing and would give up anything to read a good murder mystery.